Heartfoods Group, Inc.

An Agritech & Cleantech Company

Transforming Our Food System

Recycling food and crop waste for a more secure food future

Our Process

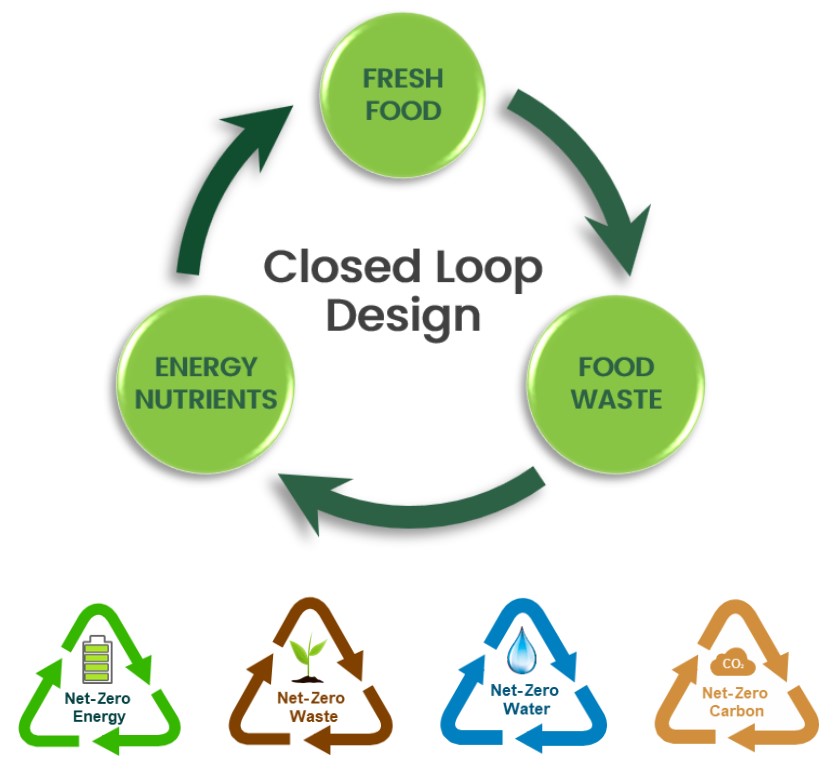

The HeartFoods’ core BioLoopTech™ System recycles the energy, nutrients, water and carbon from food and crop waste to produce green power, capture CO2 and create a robust biological live-culture liquid fertilizer, that we call “Biobrew”.

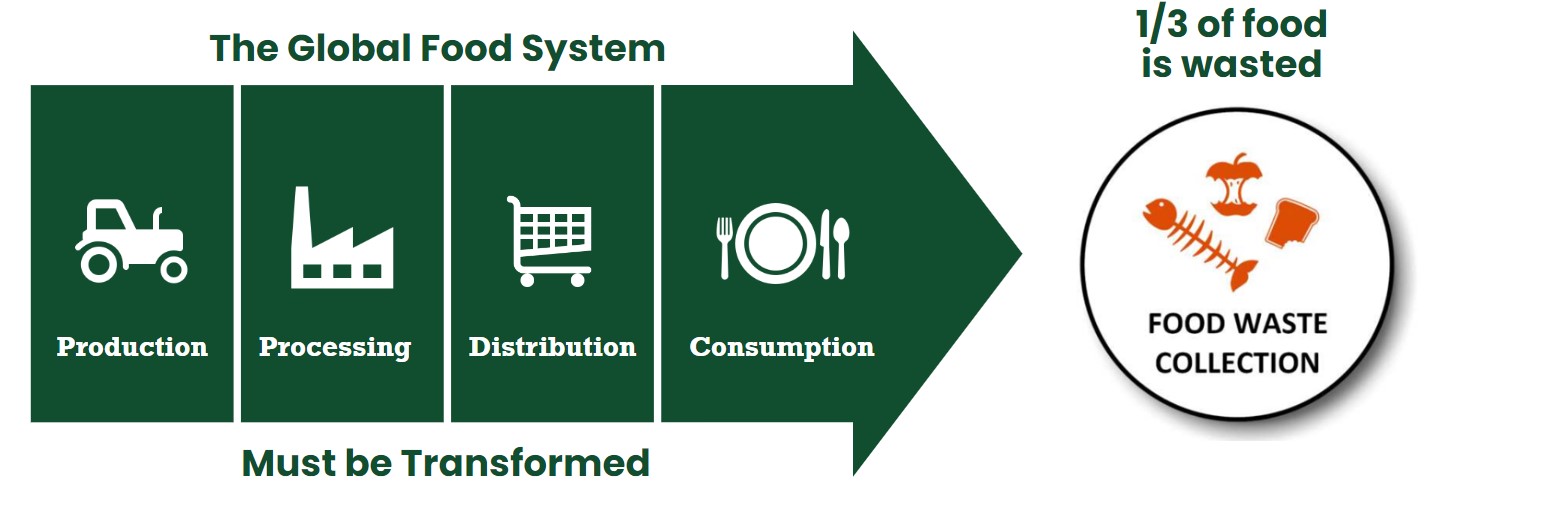

The Problem

The current global food supply chain creates food waste.

HeartFoods Community Farms touches on all four parts of the world’s food system that must be transformed:

Production, Processing, Distribution and Consumption

Why Do We Need to Change Our Food System?

Watch the short video from UNEP below

The Solution

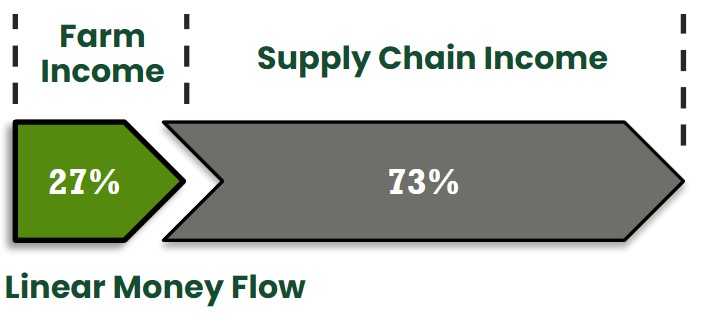

A Better Farm to Fork Economy

Current Global

Food System

HeartFoods Food System

HeartFoods products are sourced and sold within the HeartFoods community.

Transform the food system from a linear model to a circular economic model

Net Zero Design

The energy, nutrients, water and carbon in the food and crop waste is processed by the HeartFoods BioLoopTech™ System’s closed loop design.

Closed-Loop Design

Energy + Nutrients + Water + CO2

Unique Advantages

- HeartFoods’ core BioLoopTech™ System has an agritech, cleantech, green energy precedent

- Proprietary organic fertilizer made from food/crop waste

- CO2 capture & carbon reduction

- Fresh organic food can be grown year-round in any climate

- Nutritious food sold direct to customers at retail prices

- Provides local food security and jobs

- Stimulate local “circular” economies

Community Farm Option

Our Theme

Food as Medicine. HeartFoods helps grow nutritious food for healthy communities around the world.

Modular - Fully Integrated Package Systems

HeartFoods is a Design-Build-Operate entity contracting with customers to custom build their own modular BioLoopTech™ System in five markets:

Local Food Production (Community Farms)

Includes options for vertical grow rooms or greenhouse crop production

Regenerative Agriculture

Crop & animal waste converted to energy, CO2 & fertilizer for soil restoration to increase yields

Controlled Environment Agriculture

Onsite food & crop waste converted to energy, CO2 & fertilizer + increase profits

Food Processing and Manufacturing

Food waste converted to energy, CO2 & fertilizer + carbon reduction

Controlled Environment Aquaculture

Fish & shellfish solids and morts are processed + grow feed options

Community Farm [Modular Farm Option]

Structures and equipment are assembled in a shop and delivered to the site for “turnkey” operations.

Architectural Rendering

Community Farm [Campus Option]

High-tech greenhouses can be added to the modular BioLoopTech™ System based on location and customer specifications.

Architectural Rendering

Regenerative Agriculture

- Applications for restoring and enhancing soil health with biological “live culture” fertilizer while producing onsite green power, reusing and capturing CO2 and water.

Farm soil and its microbial conditions benefit from the proprietary biological additives and processes used to create a robust fertilizer

Organic Certified Fertilizer & Foods Crops

- Vertical grow rooms and high-tech greenhouse food production.

Hydroponics grow vegetables, greens, herbs, spirulina and berries in an optimal controlled growing environment

Food Industry

- The operating costs of handling onsite food waste is turned into a profit center by converting the energy, nutrients, water and carbon into valuable products.

Food waste “resource” converted into: green energy + food grade CO2 + fertilizer with overall operating carbon reduction

Recirculating Aquaculture Systems (RAS)

- An onsite BioLoopTech™ System converts the organic aquaculture waste and mortalities (AKA "morts") into green power and fertilizer, plus it captures CO2 and water.

MainStream Aquaculture

Process fish & shellfish waste solids and morts + grow feed options

Business Model

- We design and build the modular HeartFoods BioLoopTech™ facility in a shop, ship it anywhere in the world, including the equipment, and provide set-up and start-up operations.

- We train local operational staff in food/crop waste collection and processing, and, optional grow room production, produce harvesting and distribution.

- We provide on-going monthly supply of biological additives and operational support via remote monitoring and controls.

Architectural Rendering

Concept mini modular community farm design using five 20’ shipping containers

Founder

Mark Buehrer

HeartFoods CEO / Founder

HeartFoods was founded in October 2020 as a design-build-operate entity. Mark is a registered professional civil engineer, author, and inventor with over 30 years engineering experience on sustainable projects around the world, including nature-based wastewater treatment & water reuse systems, material recycling & composting facilities, and net zero living buildings. In 1995, Mark founded 2020 ENGINEERING, a professional engineering consulting firm, which has been dedicated to providing simple and innovative solutions for the long-term economic and environmental sustainability of local, national and international communities.

Example Concept Modular Farm

Contact:HeartFoods Group, Inc.

A Public Benefit Corporation

1010 C Street, Bellingham, WA 98225

(360) 671-2020

[email protected]